This article provides an online calculator for the Indexer/ATC turret/Flying shear rotary cut mechanism to quickly find the servo’s electronic gear ratio and provide additional simulation information to evaluate whether the system parameters meet the requirements. The steps are as follows:

- Enter the number(C) of Tools or Stations.

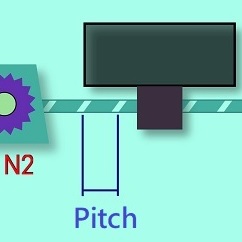

- Define Division, ie, How many PUUs betweens 2 stations.

- the Circumference(C×P) is displayed and which is used for P2-52 of Delta A2 servo.

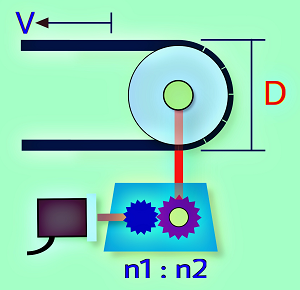

- Enter the mechanical Reduction ratio (1:1 without deceleration)

- Enter Encoder Resolution(PLS), PLS number per turn of the Encoder,ie,The number of PUUs required to make the motor rotate 1 turn when the electronic gear ratio is 1:1.

- Press the “Calculate” button to get the numerator and denominator of the E-Gear Ratio.

- Enter the positioning time T of each division to check whether the simulation result is satisfied?