<= See All alarms of Delta servo

| Name | Description | ALM | WRN | SRV ON | Clear Way |

|---|---|---|---|---|---|

|

AL.015 Positive limit error |

Positive limit DI.PL(0x23) error | ⊗ | Yes | automatically cleared after the motor moves away from the limit |

<= See All alarms of Delta servo

| Name | Description | ALM | WRN | SRV ON | Clear Way |

|---|---|---|---|---|---|

|

AL.015 Positive limit error |

Positive limit DI.PL(0x23) error | ⊗ | Yes | automatically cleared after the motor moves away from the limit |

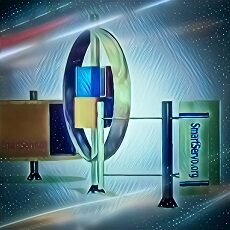

According to the literature, the Darrieus vertical axis wind turbine characterized by high efficiency but it is difficult to be self-starting. I couldn’t understand when I first came into contact with it. Since high efficiency means that it has torque, why can’t it start by itself? Later I realized that its efficiency must appear at a higher speed (similar to the high gear of a car), As for how high the speed should be? Usually 2~6 times faster than wind speed. This puzzles me even more, because the wind turbine is driven by the wind, why can it revolve faster than the wind speed? It seems that an experiment must be done, seeing is believing …

Due to the need for environmental protection and the fight against global warming, the development of renewable energy is urgent. In addition to solar energy, wind energy has attracted the most attention. In order to use wind energy, mankind has invented Wind Turbine for centuries. The wind turbine can convert wind energy into the rotating mechanical energy, and the torque generated by its main shaft can be used to drive a load, such as a generator or a water pump, for power generation or irrigation. According to the direction of the rotation axis, wind turbines can be divided into two types: horizontal axis and vertical axis.

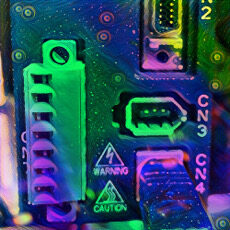

In PLC applications, sometimes it is necessary to communicate with the servo. The easiest way is to use the modbus protocol through RS-232/485. This is a very cost-effective way for small systems with few axes. However, it is often a pity that the application is limited due to the lack of rapid response. For this kind of application, this article takes Delta A2 servo as an example, and provides some acceleration methods to increase the refresh rate of communication and make the command response more quickly. Interested readers can refer to it.

<= See All alarms of Delta servo

| Name | Description | ALM | WRN | SRV ON | Clear Way |

|---|---|---|---|---|---|

|

AL.503 STO Diagnosis |

STO self-daignosis error | ⊗ | NO | Cycle power on |

<= See All alarms of Delta servo

| Name | Description | ALM | WRN | SRV ON | Clear Way |

|---|---|---|---|---|---|

|

AL.502 STO B lost |

STO_B lost (signal loss or signal error) | ⊗ | NO | Cycle power on |

<= See All alarms of Delta servo

| Name | Description | ALM | WRN | SRV ON | Clear Way |

|---|---|---|---|---|---|

|

AL.501 STO A lost |

STO_A lost (signal loss or signal error) | ⊗ | NO | Cycle power on |

<= See All alarms of Delta servo

| Name | Description | ALM | WRN | SRV ON | Clear Way |

|---|---|---|---|---|---|

|

AL.500 STO Enabled |

Safe torque off function (STO) is enabled | ⊗ | NO | DI.ARST |

<= See All alarms of Delta servo

| Name | Description | ALM | WRN | SRV ON | Clear Way |

|---|---|---|---|---|---|

|

AL.025 |

The internal memory of the encoder and the internal counter are in error | ⊗ | NO | Re-power on |

<= See All alarms of Delta servo

| Name | Description | ALM | WRN | SRV ON | Clear Way |

|---|---|---|---|---|---|

|

AL.026 |

The error of the internal data has been detected for three times continuously | ⊗ | NO | Re-power on |